Linx CSL10 Laser Coder

The Linx CSL10 laser coder is a high specification, 10 W CO2 scribing laser coder. Laser is economical, yet versatile for a wide range of laser marking applications.

You may have a fast line with simple code requirements or a slower line with a more complex code. So Linx CSL10 offers you the most flexible solution for quality coding onto a wide range of materials.

Fast

More Applications

Reliable

Easier to Integrate

Technical Specification

*Tube life may vary according to application.

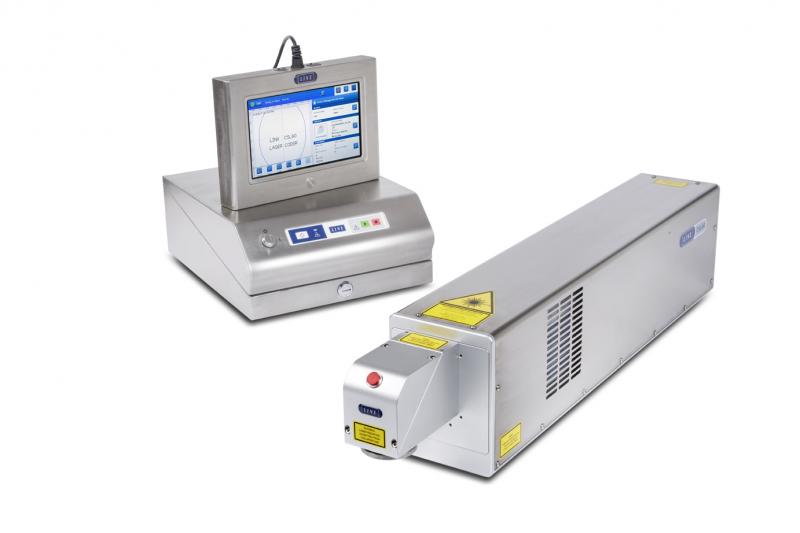

Linx CSL30 Laser Coder

Key Benefits of Linx CSL30 Laser Coder

Watch the Video: http://www.youtube.com/watch?v=hNTtn0cGWbw

Linx CSL30 Laser Coder Marking

The Linx CSL30 Laser Coder is a flexible, 30 W CO2 scribing laser coder. Laser coder delivers high-speed coding with low maintenance – with no compromise on code quality.

The Linx CSL30 laser coder produces sharp codes on fast lines. It marks even on hard-to-mark materials such as glass and rubber. It can meet your coding requirements as they change – such as changes in-line speed, code complexity, or material types – with no additional investment needed.

Fast

More Applications

Reliable

Easier to Integrate

*Tube life may vary according to application

Technical Specification

*Tube life may vary according to application.

Linx CSL60 Laser Coder

Key Benefits of Linx CSL60 Laser Coder

Please watch the Video of Linx CSL60 Laser Coder: https://www.youtube.com/watch?v=fhBLl_8Orp4

You may download

Linx CSL60 Laser Coder Marking

The Linx CSL60 Laser Coder is a 60 W CO2 scribing laser coder. Laser coder delivers high-speed coding in demanding production environments. Works with low maintenance and no compromise on code quality.

The Linx CSL60 laser coder produces sharp codes on fast lines. Powerful processor makes it is ideal for complex coding onto hard to mark materials such as glass and rubber. It can meet your coding requirements as they change. Changes inline speed, code complexity, or material types require no additional investment.

Fast

More applications

Reliable

Easier to integrate

*Tube life may vary according to application

Technical Specification

Linx SLHP Laser Coder High Performance

The Linx SLHP Laser Coder (Scribing Laser High Performance). It produces superior quality codes at some of the fastest speeds currently available on the market.

High speed/High power

The Linx SLHP Laser Coder is a high power 120W CO2 laser which can code accurately at high speeds. For example in excess of 70,000 bottles per hour on high speed beverage production lines. High power allows many different materials to be marked quickly and permanently. This is includes hard-to-mark substrates such as glass, rubber and PET.

Quality coding

Due to vector – generated codes Linx SLHP laser coder accurately reproduce graphics. Therefore codes are matching packaging design with unobtrusive coding. It serves as anti-counterfeiting measure for premium products such as spirits, perfumes, cosmetics, tobacco as well as automotive products.

The high power of the laser means a shorter dwell time on the product. So it reduces the chance of outside interference during coding. This is resulting in crisp accurate marking.

The laser’s large scan area enables coding of multiple lines. It codes a wide variety of data. Start from simple date and production details up to legislative text, barcodes and logos. Complex codes for the pharmaceutical industry include GS1 and 2D Data Matrix codes.

Reliable and Future-proof

Both the laser coder marking head and the supply unit are IP56 rated. This is ensure reliable operation in harsh production environments.

Efficient use of the laser source prolongs the life of the laser tube. It makes the Linx SLHP laser coder a long-term and reliable coding solution. Laser doesn’t require factory air or water for cooling. Cooling is integral to the laser, which means no ongoing consumable costs.

The Linx SLHP laser coder can deliver extra power, speed and codes. This is due to a wide range of coding formats and longer tube life. They are available when you need them, with no additional expenditure.

Linx FSL20 & FSL50 Fiber Laser Coders

The Linx FSL20 and FSL50 fiber laser coders offer a cost-efficient and hugely flexible coding solution. Fiber laser coders codes on the widest range of hard materials and substrates. They are good for marking on metals and plastics. Lasers applicable for static applications and moving production lines. Linx fiber laser coders are created to minimize line downtime. Because of that they improve reliability and reach maximum level of productivity.

Key Benefits

Permanent traceability

Linx Fiber laser coders can permanently mark on a wide range of materials, including metal, rubber, plastic, and packaging foils. The very fine spot size creates excellent quality codes and makes Linx Fiber laser coders ideal for marking on very small components. They are good also for printing large amounts of information onto small areas. Consequently any text, machine-readable codes, graphics and logos are all marked with extreme clarity for traceability. Therefore fiber laser coders are ideal for pharmaceutical, medical devices, automotive and electronics industries, as well as FMCG packaging.

Linx Fiber laser coders can be tailored to the precise requirements of each product – whether for static or moving applications. Choice of four different lenses makes Linx Fiber laser coders extremely efficient in use with no compromise on code quality or speed. Available power options of Fiber lasers makes them workable at a higher lines’ speeds.

Easily integrated

The Linx FSL20 and Linx FSL50 fiber laser coders have one of the smallest supply units and marking heads on the market. Due to that it enable easy integration into existing line or static coding applications. Also it brings minimum disruption to existing workflows.

The choice of two beam orientation aids integration, allowing coding in any direction. Certainly a Beam Turning Unit allows the head to rotate through 90° adding value to laser design. An internal air cooling system as a result means no restriction on location.

Reduce downtime

As with all Linx coders, Linx Fiber laser coders have a robust design which delivers continuous, reliable coding.

With a laser source lasting over 100,000 hours, and with no pump chamber maintenance needed, end user will experience less downtime on the line. Air cooled fiber laser is also more energy efficient and require less maintenance compare to alternative water-cooled ones. Fiber laser can operate continuously in a wide range of environments due to IP54 rated marking heads.

Message creation is quick and simple with LinxDraw® software, via a colour touch screen or from a separate PC. Therefore this require less time spent on product setup and changeovers.